Glass Manipulator

Top Glass Manipulator Manufacturer | Mova

90% of glass manufacturers face challenges in lifting and transporting glass. MOVA has meticulously analyzed different glass handling requirements from among the hundreds of glass manufacturers we have served to provide customized glass manipulator solutions.

Showing all 4 results

Mova glass manipulators can meet all your needs.

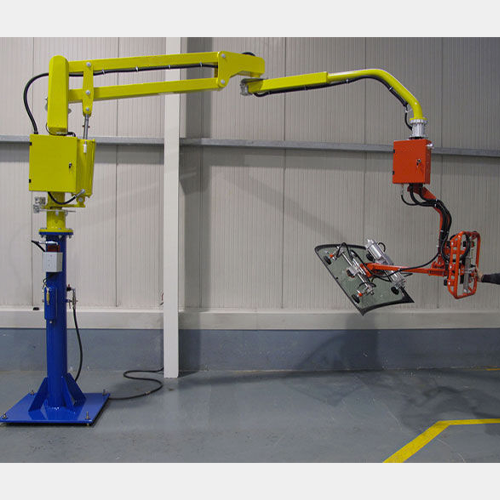

A glass manipulator is an important tool mainly used in factory production to transport, handle, and operate glass panels accurately and safely. This specialized equipment improves productivity in the manufacturing and construction industries by allowing operators to move large, bulky glass panels with ease. glass manipulators grip the glass securely, allowing for smooth operation, whether lifting, tilting, or rotating glass panels to the precise angle required for installation or further processing.

How glass manipulators Solve the problem of manual glass handling

Mova glass manipulators address one of the most challenging aspects of glass handling – lifting and moving heavy and fragile material safely and efficiently. We use the vacuum generator to produce both positive and negative air pressure. By using this different pressure, the glass manipulator’s vacuum suction cups can securely attach to the surface of the glass, ensuring a firm and reliable hold.

Normally, Mova will recommend users choose an industrial manipulator with a suction cup clamp specially used for handling glass to customize their glass manipulator.

Workers can control this pressure simply with buttons on the control handle. Just press the glass surface down on a suction cup, then hit the button to regulate negative pressure, and see – you can now lift and move glass weighing up to 300kg.

But it’s not only about lifting. With the same handle, workers can also flip the glass with ease, or shift its position up, down, left, or right. The best part is the glass manipulator, with its column as a center, can freely move within a 1.5m radius. This flexibility makes it a reliable solution for manipulating cumbersome or oversized glass pieces, significantly lessening the risk of damage or human injury during the handling process.

In this manner, a glass manipulator proves to be a practical day-to-day solution that makes glass handling not only a safer task but an easier one too.

How to ensure the safety of the glass manipulator

When dealing with the transport and installation of glass, people are always concerned about whether the glass will suddenly drop during handling. This fear is not unfounded, as the consequences of glass falling can cause costly material damage and serious injuries. However, Mova offers a reassuring answer to these safety concerns.

Mova glass manipulators are equipped with specifically designed features to prevent the accidental release of glass. These designs can greatly minimize the likelihood of a sudden drop.

The following explanation will delve into how Mova glass manipulators ensure safety during glass handling. In general, the sudden fall of glass during transportation with a glass manipulator may be due to the following two situations:

Sudden Air Supply Interruptions in Factory

Although modern factory equipment is very reliable, in some cases the air supply can be interrupted unexpectedly. This might affect the vacuum suction power of the glass manipulator. To solve this problem, Mova glass manipulators are equipped with two critical safety features:

Backup Air Reservoirs: The Backup air reservoir acts as a safeguard against abrupt air outages in factories ensuring that the suction cups maintain their grip on the glass, thus preventing any accidental drops.

Electronic Pressure Detection System: This device continuously monitors air pressure levels. If the air pressure drops under the safety level, it will trigger an automatic alarm, alerting the operator to the potential risk, and allowing for timely intervention.

Air Supply Interruptions caused by glass manipulator breakdown

During glass manipulator use, there may be instances of equipment damage or air tube aging that leads to breakages. Regular maintenance is required to keep the glass manipulator in good condition, and Mova has two solutions to further prevent accidental glass drops:

Special Air Loss Protection Suction Cups: These vacuum suction cups trigger counteracting suction force instantly when the device loses air suddenly, ensuring that the glass does not drop abruptly. They provide 2-3 minutes of additional time to react.

Protection Hooks: To further ensure safety, we set hooks under the gripping device as a fail-safe. If the glass does drop suddenly due to a loss of suction, it will initially fall onto the safety hook instead of dropping directly. It gives added protection and minimizes the risk of damage.

MOVA: customized your glass handling solution

Different glass manufacturers face unique challenges in lifting and transporting glass. The customized services offered by Mova enable every type of glass product to find the glass manipulator that best suits its needs.

Mark-free Suction Cups for LCD Screen Handling

LCD screen glass is a material that requires extremely high precision but is not very heavy. What you need to worry about during transportation is whether the vacuum suction cup of the glass manipulator will leave traces on its surface. In response to this concern, Mova usually replaces the special vacuum suction cup when designing the glass manipulator. This suction cup is made of special material and will not leave any traces on the surface in contact with the glass.

Hovering feature for automotive glass

In the scene of transporting automotive glass, there is generally a need for glass installation. People need the glass to hover at a specified height and maintain a certain flip angle. The design of automotive glass manipulators takes into account every nuance of automatic glass lifting. With customization at the heart of their development, these glass manipulators incorporate intelligent ergonomics and precise control systems that allow operators to maneuver the glass with both accuracy and ease.

Why choose the Mova glass manipulator

With Mova’s customized glass manipulators, you can have all the features you need. The advantage of customized design lies in understanding every requirement of glass handling and production. From the type of grippers needed to the level of safety measures required, customization caters to these diverse needs flawlessly.

As an industrial manipulator manufacturer integrating R&D and manufacturing, Mova not only customizes glass manipulators with different loads, lifting heights, and moving radii, but we can also customize the modules and functions of the glass manipulator according to customer needs. This means that whether you need to handle construction glass, LCD glass, or automobile glass, we can design the most suitable glass-handling robotic arm product for you.