Manipulator arms for panel handling

Panel lifter manufacturer | Mova

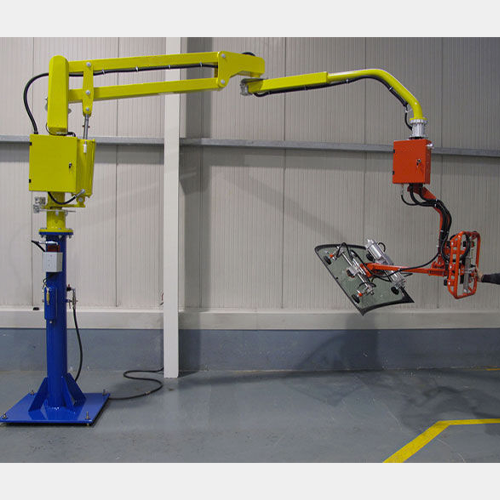

Panels are ubiquitous components, commonly used across a myriad of sectors including construction, automotive manufacturing, and electronics. These panels can be made from a variety of materials such as steel, plastic, wood, or metal, and vary significantly in weight, ranging from as light as 20 kilograms to as heavy as 200 kilograms. The manipulator arm for panel handling is designed to grip, lift, and position panels with precision and ease.

Showing all 7 results

Manipulator arms for panel handling

The substantial size and weight of panels present significant challenges for manual handling. The physical demands and inefficiencies of transporting heavy panels solely through human effort highlight the limitations of manual labor. This is why the manipulator for panel handling becomes indispensable.

The Mova manipulator arm can securely hold various types of panels during the handling process. By mechanizing the manipulation of heavy and unwieldy materials, these manipulators not only reduce the physical strain on workers but also significantly increase the efficiency and accuracy of operations.

How does the manipulator arm assist panel handling

The manipulator arm for panel handling is a handling assist designed to enhance the handling of both metallic and non-metallic panels with precision and safety. These arms are generally equipped with grippers such as suction cups or electromagnetic grippers. These grippers can securely grasp panels, allowing them to be not only lifted and transported but also hovered or rotated.

This capability is particularly beneficial for tasks involving the positioning of panels in orientations that would be cumbersome or unsafe to achieve manually.

The manipulator arms for panel handling require an operator to manually guide the actions of the grippers. Operators interact with the manipulator through a control panel equipped with buttons, switches, or joysticks. These controls enable the precise movement, gripping, and release of panels.

The operator can maneuver the arm to the desired location, securely hold the panel, and then accurately transport and place it, ensuring both the safety of the material and the efficiency of the workflow.

This level of control is vital in environments where precision and safety are paramount, such as in assembly lines or construction sites where improper handling could lead to damage or injury.

Mova panel manipulators V.S. Other handling methods

Overall, aside from panel-handling manipulators, there are three other methods for heavy panel handling. These include manual handling by workers, fully automatic robotic arms, and traditional panel lifters(a simple tool that lifts panels vertically by manually turning a crank). The following sections will compare manipulators with these panel handling methods across several dimensions, highlighting their respective advantages and disadvantages.

Efficiency

Manual Handling: Least efficient, with low speed and high labor fatigue.

Traditional Panel Lifters: Slightly more efficient than pure manual handling but limited to vertical movements and still labor-intensive.

Fully Automatic Robotic Arms: Highly efficient with continuous operation capability, though complex setups can hinder flexibility.

Manipulator Arms: Offer good efficiency, enhancing speed and reducing labor fatigue compared to more manual methods.

Cost

Manual Handling: Low initial cost but potentially high due to labor costs and risk of injury.

Traditional Panel Lifters: Moderate cost, requires investment in equipment but still relies on labor.

Fully Automatic Robotic Arms: High initial cost, maintenance, and programming expenses, making it less feasible for smaller operations.

Manipulator Arms: Reasonable initial investment, lower maintenance costs than fully automatic systems, and reduced labor costs.

Precision

Manual Handling: Low precision, highly dependent on worker skill and conditions.

Traditional Panel Lifters: Moderate precision, primarily in vertical lifts with no orientation control.

Fully Automatic Robotic Arms: High precision but it requires complex programming and is only suitable for fixed production lines.

Manipulator Arms: Good precision, with better control over placement and orientation than manual methods.

Workforce requirement

Manual Handling: Requires a large workforce, physically demanding, high turnover.

Traditional Panel Lifters: Still requires considerable human effort, and does little to reduce workforce demands.

Fully Automatic Robotic Arms: Reduces workforce size but requires highly skilled operators and programmers.

Manipulator Arms: Reduces the physical demand on workers, requiring fewer people who can focus on control and supervision.

How to choose your manipulator arm for panel handling

Selecting the appropriate manipulator arm for panel handling requires a careful assessment of your panel handling needs and operational conditions.

Consider the types of panels that will be handled: including their material, size, and weight. Different panel-handling grippers, such as suction cups for glass or smooth surfaces and clamps or magnets for metal, are crucial for matching the manipulator arm to the panel’s characteristics.

Evaluate the workspace environment: If space is limited, consider a manipulator with a compact design or one that can be moved.

Factor in the load capacity and the range of motion needed: We need to consider both the vertical and horizontal range that the panel needs to be moved—to ensure the manipulator arm for panel handling can perform the required tasks efficiently. By aligning these factors with your panel handling tasks, you can select a manipulator arm that enhances productivity while ensuring safety and precision in your panel handling processes.

If you think this process is very complicated, don’t worry. When purchasing panel-handling manipulators from Mova, there will be a professional engineer who will tailor a manipulator arm solution specifically for your usage needs and actual work environment. From the design blueprints of the manipulator arms to the manufacturing and installation of each component, we ensure the quality of your manipulator arms for panel handling.

Why choose Mova as your panel-handling manipulator supplier

If you are still unsure about how to choose your panel-handling manipulator even after reading the above introduction, don’t worry, when you purchase a manipulator for panel handling from Mova, an engineer will communicate with you, meticulously recording all your requirements – from the panel handling needs to equipment budget, and will custom the most suitable manipulator for you.

By choosing Mova as your panel-handling manipulator manufacturer, you will experience meticulous pre-sales customization service, professional manipulator arms production and installation, and thoughtful after-sales service. As a company that has been committed to the production and sales of industrial manipulators for 15 years, Mova is dedicated to enabling customers to purchase the most suitable panel-handling manipulator arm products at the most affordable prices, helping various industries solve material handling problems.