Bag Lifter

Best bag lifter supplier | Mova

As we all know, flexible packaging bags are among the most common forms of heavy-item packaging, typically transported in the form of paper bags or woven sacks, such as cement, fertilizers, grains, and other materials. Mova has developed several manipulators for bag handling specifically designed for handling flexible packaging bags, suitable for a variety of different material handling scenarios.

Showing all 6 results

Industrial manipulator for bag handling

The bag lifter (industrial manipulator for bag handling) is commonly used for loading, unloading, and palletizing flexible packaging flexible packaging bags items, typically weighing around 50kg. Workers need to be able to quickly and securely pick and place the flexible packaging bag to meet the fast-paced demands of loading and unloading goods.

Flexible packaging bags made of different materials need to have different bag lifter solutions. Mova provides customized manipulators for bag handling, from the grippers to the types of manipulator, to select the most suitable handling solution.

How to choose your bag lifter

The design of the gripper of the manipulator for bag handling is not complicated, and the carrying requirements are relatively simple compared to other products. In general, it only needs to meet the workflow of gripping, lifting, moving, and putting down, and ensure that it can stack neatly. However, concerning the differences in the products of different flexible packaging bags and the materials of the bags, you may want to consider the following questions before choosing a manipulator for bag handling.

- What material is your flexible packaging bag, and is it breathable?

- How much do your bagged products weigh?

- How high is the lifting height you need?

- Can there be a gap when stacking your products?

Mova industrial manipulator engineers categorize the manipulator for bag handling into the following two types.

Bag lifter with gripper

The operator needs to control the opening and closing of the gripper by pressing the button on the handle. Place the grippers on both sides of the flexible packaging bagged heavy items and then closed to grasp the flexible packaging bags.

Then press the other button on the handle to lift the heavy item. With the assistance of the manipulator’s floating function, workers are able to easily lift and move a 50kg flexible packaging bags within a 3-meter range.

Mova has two types of bag lifters with gripper. One is the articulating jib crane equipped with the gripper for bag handling, and the other is a patented product by Mova called the Cement Machine.

Articulating Jib Crane with Bag Gripper: The articulating jib crane with bag gripper raises the product by lifting steel wire or chains through a hoist. The crossbars of the articulating jib crane cannot move up and down.

Mova Cement Machine: Mova Cement Machine adds cylinders and ingeniously modifying the crossbar structure, allowing for the direct handling of flexible packaging bags via the vertical or horizontal movement of the crossbar.

Bag lifter with suction cup

Compared to bag lifter equipped with grippers, vacuum suction cup manipulators for bag handling are simpler to operate. All that is required is to place the suction cup on the flexible packaging bags, and then pull on the vacuum pump handle to easily lift a 40kg load. This operation can be performed single-handedly by a skilled worker.

It is worth noting that, although this type of manipulator for bag handling is convenient to use, it has certain requirements for the material of the flexible packaging bags. Overly breathable woven flexible packaging bags are not suitable for this kind of bag lifting machine.

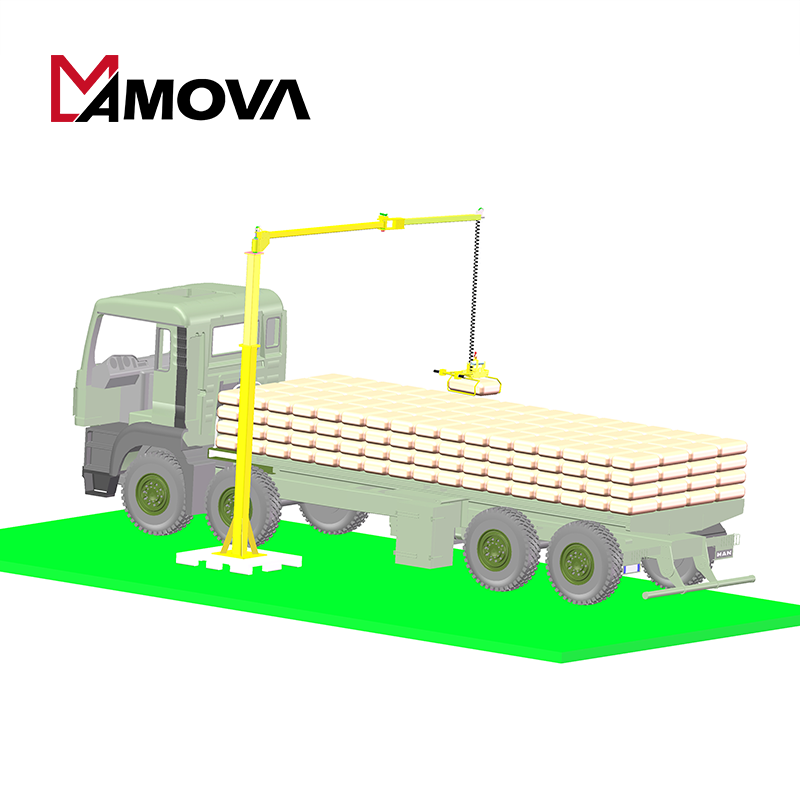

Articulating Jib Crane with Suction Cup: This manipulator for bag handling is configured with a vacuum suction cup fixture based on the articulating jib crane. It firmly adsorbs flexible packaging bags on the suction cup using the principle of vacuum pressure. The force arm of the articulating jib crane for bag handling can fold, which means that the operator can move freely within a certain range horizontally when handling the heavy object.

Vacuum Tube Lifter for Bag Handling: The vacuum tube lifter is usually equipped with special material vacuum tubes, ensuring a certain vacuum state inside the tube through a blower or vacuum pump. A vacuum tube lifter for bag handling is generally fitted with the jib crane, offering simple operation to easily and swiftly lift heavy objects.

Why choose Mova as your bag lifter supplier

If you are still unsure about how to choose your bag lifter even after reading the above introduction, don’t worry, when you purchase a bag lifter from Mova, an engineer will communicate with you, meticulously recording all your requirements – from bag handling needs to equipment budget, and will custom the most suitable manipulator arms for you.

By choosing Mova as your bag-handling manipulator manufacturer, you will experience: meticulous pre-sales customization service, professional industrial manipulator production and installation, and thoughtful after-sales service. As a company that has been committed to the produce and sales of industrial manipulator for 15 years, Mova is dedicated to enabling customers to purchase the most suitable bag-handling manipulator products at the most affordable prices, helping various industries solve bag handling problems.