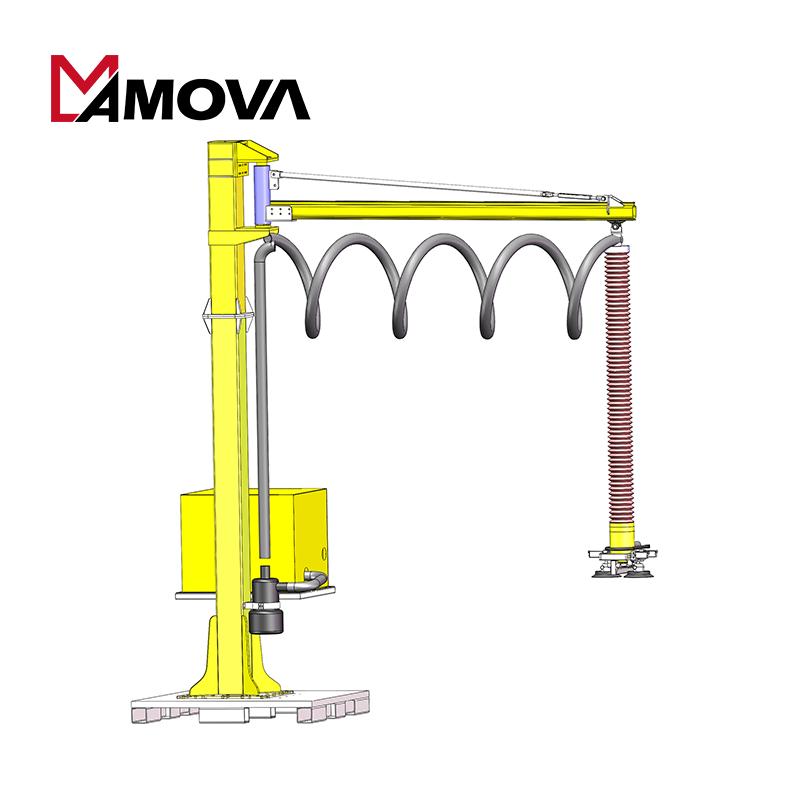

Industrial Manipulator for Drum Lifting

Best drum lifter manufacturer

Drums are a common product in industrial production lines, with light drums weighing up to 50kg and heavy drums weighing up to 500kg. Moving such heavy drums manually without any assistance is obviously a very difficult task, introducing many hazardous factors to production safety and efficiency.

Therefore, Mova drum manipulator should be your first choice to consider. Drum manipulators can meet the needs of most drums handling in production lines and factories, including but not limited to lifting, moving, and rotating.

Showing all 5 results

Industrial manipulator for drum lifting

Depending on the material and structure of different drums, Mova drum manipulators can be equipped with various grippers to meet customer needs at the lowest cost. This article mainly introduces three types of grippers for drum manipulators to grab drums and their usage.

Semi-circular gripper for the drum manipulator

The semi-circular gripper of the drum manipulator has a scissor-like gripping structure with a pneumatic power device at the end of the “scissor.” The metal gripper grabs the drum by swinging open and closed. The semi-circular gripper of the drum manipulator is customized according to the diameter of the drum, so the diameter range of the drums that the same gripper can grab is relatively fixed.

When operating a drum manipulator equipped with a semi-circular gripper, the operator needs to first open the semi-circular metal gripper, place the drum product within the gripping range, and then press the button on the control panel to adjust the air pressure for gripping and handling.

- Can rotate drum product

- The drum must has fixed diameter

- No special requirements on the material of the drum

The V-shaped gripper for the drum manipulator

The V-shaped gripper of the drum manipulator consists of two parallel metal clamping plates located on the end of the rigid arms. The two metal plates move in parallel to grip the material through pneumatic pressure control. The V-shaped gripper has a larger gripping range and can adapt to drums of different diameters.

When the operator uses a drum manipulator equipped with a V-shaped gripper, the metal gripper needs to be opened first, then the drum to be moved need to be placed between the metal crossbars before gripping. After making sure the two crossbars are completely attached to the drum body, press the lift button and the drum manipulator will lift the drum to the height required by the operator by adjusting the air pressure.

- Can rotate drum product

- Can grip drums with different diameter

- Requires certain hardness of the drum material

Gripper working on the top of the drum

This gripper for drum manipulators is a special gripper designed specifically for drums with a protruding edge on the top. It mainly lifts and transports by hooking the protruding edge of the drum. In use, the operator needs to manually hang the small hooks on the edge of the paint bucket before lifting.

The gripper design of this drum manipulator is mainly used for translating products. The special gripping method means it cannot flip the products. But this low-cost gripper of drum manipulator can be chosen when the drum products with suitable protruding edges for gripping.

- Product cannot be flipped

- Fixed diameter needed

- Drum structure needs special edge

The suction cup gripper for the drum manipulator

The suction cup gripper utilizes the principle of vacuum suction. It uses a vacuum pump or vacuum blower as a vacuum source to generate a vacuum at the suction cup end, firmly attaching the drum for handling.

The suction cup gripper can be applied to the top or side of the drum. The operator needs to make the suction cup gripper adhere closely to the drum surface before exhausting the air.

Using a suction cup drum manipulator has certain requirements on the product specifications of the drum. First, the drum surface must be smooth with sufficient suction area. Second, the material of the drum must have a certain hardness and not easily deform. Given sufficient bearing area on the drum, the suction cup gripper can handle products of any diameter within the weighing range.

- Product cannot be flipped

- Requires a certain bearing area

- Requires the drum material to have a certain hardness

How to choose your drum manipulator

The drum manipulator is a non-standard customized product. When choosing a drum manipulator, there is usually one-on-one communication between the drum manipulator engineer and the buyer to customize the drum manipulator.

In general, when customizing a drum manipulator, the engineer will first collect the basic information of the product to be handled and select the gripper type accordingly. The drum manipulator engineer will prioritize the following characteristics of the drum:

The drum material: whether it is rigid or flexible, and prone to deformation.

The drum structure: whether there is adequate bearing surface on the top and sides for a suction cup gripper. Whether the top edge has protrusions to allow using a gripper on the drum top.

Next, the engineer will consider the customer’s handling needs, usually including:

- Required lifting height and working range

- Whether the drum product needs flipping

- Any floor space limitations

- Specific handling accuracy requirements

- If the manipulator needs to be portable

In addition, customizing a drum manipulator needs to consider many other factors. Therefore, you need a manipulator manufacturing expert more to solve the problems for you. Mova Machine is committed to the manufacturing and customization of drum manipulators. We have a professional engineering team and solution design process that can tailor manipulator solutions for drums according to different needs.